Global Plastic Pallet Market Share (2018-2023)

Pallets are horizontal platforms which offer a base for storing, handling, assembling and transporting product...

Plastic production machines and equipment are the driving force behind the manufacturing of countless plastic products that have become an integral part of our modern lives. From household items to automotive components, medical devices, and even aerospace applications, these machines play a crucial role in shaping and forming plastic materials into desired shapes and forms. The plastic industry relies on a diverse range of specialized machines and equipment to meet the ever-growing demand for plastic products, ensuring consistent quality, efficiency, and cost-effectiveness.The continuous advancements in technology and materials science have led to the development of more sophisticated and efficient plastic production machines, enabling manufacturers to push the boundaries of innovation and meet the evolving needs of various industries. These machines are engineered to handle different plastic materials, production volumes, and product complexities, ensuring that the plastic industry remains at the forefront of manufacturing excellence.

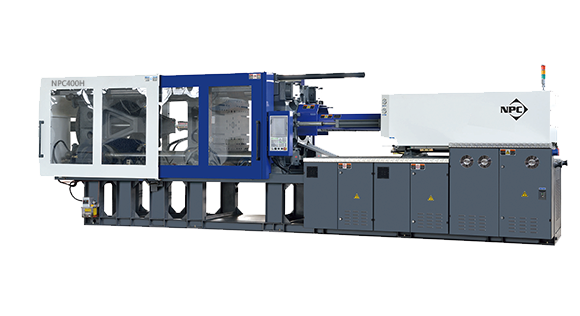

Injection molding machinery is one of the most widely used and versatile plastic production equipment. These machines work by melting plastic pellets or granules and injecting the molten material into a mold cavity under high pressure. The molten plastic takes the shape of the mold and solidifies as it cools, creating the desired product. Injection molding machines are highly adaptable and can produce complex shapes with intricate details, making them suitable for manufacturing a wide range of products, including toys, containers, automotive parts, and electronic components.

A mould, or mold, is a crucial component in plastic production processes, as it defines the shape and features of the final plastic product. Moulds can be made from various materials, such as steel, aluminum, or specialized alloys, and are designed and manufactured with precision to ensure accurate replication of the desired product shape and dimensions. They can range from simple designs for basic shapes to highly complex geometries for intricate products, incorporating features such as runners, gates, and vents to facilitate the flow of molten plastic and the removal of air or gases.

An extruder is a machine used to continuously produce plastic products with a constant cross-sectional profile, such as pipes, tubing, sheets, or filaments. The extrusion process involves feeding plastic pellets or granules into the extruder’s hopper, where they are melted and mixed by a rotating screw. The molten plastic is then forced through a die, which shapes the plastic into the desired cross-sectional profile. Extruders offer several advantages, including high production rates, continuous operation, and the ability to produce long, consistent lengths of plastic products. They are widely used in various industries, such as construction, packaging, automotive, and 3D printing, and can process a wide range of thermoplastic materials.

Finding the perfect product for your needs is just a click away! We offer a comprehensive catalog packed with detailed information on all our offerings. Download your copy today and delve into the vast selection we have available. Within the catalog, you’ll find clear descriptions, specifications, and images to help you make informed decisions. Whether you’re searching for specific items or simply browsing for inspiration, our catalog is your one-stop resource. Once you’ve had a chance to review the catalog, feel free to send us an email with any questions or specific requests you may have. Our knowledgeable team is here to assist you and ensure you find the perfect solution for your needs.

Pallets are horizontal platforms which offer a base for storing, handling, assembling and transporting product...

Plastic is a word that originally meant “pliable and easily shaped.” It only recently became a name for a...

In an effort to provide a consistent metric to guide the efforts of sustainability for plastics in the Circula...

Since the introduction of engineering-grade resins and plastic materials in the 1950s, many parts previously f...

Polycarbonate and Acrylic are both well known as transparent plastics. They have wide applicability in a numbe...

The BPF reflects on its participation in ‘Arabplast’ With a booming construction industry and a ready supp...